Supporting

Imidazo-fused N-heterocycles are high-value structural units in tremendous naturally occurring compounds, biologically active molecules and functional materials [1]. During the past decades, much effort has been paid to their synthesis and functionalization [2-4]. Benzo[d]isothiazole 1,1-dioxides are an extensively valuable class of sultam molecules, possesses a range of biological activities [5, 6]. Recently, the imidazo-fused benzo[d]isothiazole 1,1-dioxides have engrossed a growing interest from both synthetic and medicinal scientists for drug discovery, as these compounds can exhibit interesting pharmacological and therapeutic effects. Despite their significance, the synthetic strategies for such N-bridged heterocycles are limited. In 2022, Sun and Yu reported the heterogeneous synthesis of benzo[d]imidazo[1,5-b]isothiazole 5,5-dioxide (BIIO) derivatives through the visible light induced-annulation of benzo[d]isothiazole 1,1-dioxide and N-phenylglycine with CsPbBr3 [7] or oxygen-doped g-C3N4 [8] as the photocatalyst. Later, Yu, Li and Chen disclosed the homogeneous photosynthesis of BIIO in the presence of Eosin Y as the photocatalyst (Scheme 1a) [9]. Despite these advances, the employment of un-commercial N-phenylglycine as the methylene source led to the inevitable formation of large amounts of aniline side product. Nevertheless, the requirement of harmful and/or un-commercial photocatalyst involves a common limitation to their large-scale and industrial application. Clearly there is an urgent demand for novel synthetic strategies, able to construct BIIO in a more cost-effective and eco-friendly manner.

Scheme 1

Scheme 1. Annulation of benzo[d]isothiazole 1,1-dioxides.

Organic electro-synthesis has gained more and more attention in sustainable organic synthesis because it can produce reactive radical intermediates through a direct single-electron-transfer manner [10-16]. Most electrochemical reactions require electrolyte additives [17-27] to ensure adequate ionic conductivity, which not only result in tedious operation procedures and the formation of chemical waste but also added production cost. Similar problems arise from the employment of redox mediators [28-35], which are frequently use to eliminate kinetic inhibitions associated with the heterogeneous electron transfer, avoid electrode passivation and achieve better selectivity [36]. Hence, the development of redox mediator- and electrolyte additive-free [37-44] electrochemical reactions is highly desirable.

Paraformaldehyde is regarded as one of the most abundant and cost-effective methylene sources and has been extensively applied to construct a variety of value-added chemicals [45-50]. In view of the key iminium ion intermediates generated from N-phenylglycines and sultams in the photocatalytic protocols, we speculated that the iminium ion intermediates can be generated with paraformaldehyde as the methylene source via Mannich reaction. Such processes are highly desirable in green chemistry, because potentially tedious workup procedures and the generation of aniline side products can be avoided. Herein, we report the successful development of an electrochemical [2 + 2 + 1] annulation for the construction of BIIO. Advantageously, this process proceeds in a catalyst-, redox mediator-, electrolyte- and chemical oxidant-free fashion to yield a diversity of functionalized BIIO (Scheme 1b).

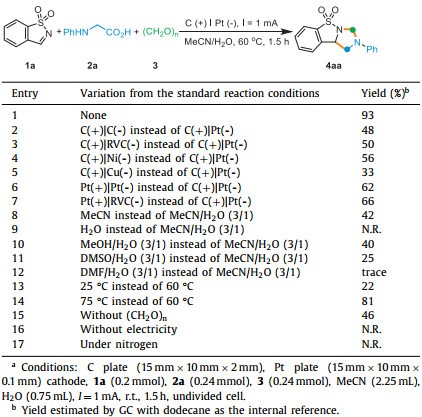

In the beginning, the reaction conditions for the electrochemical annulation of benzo[d]isothiazole 1,1-dioxide (1a), N-phenylglycine (2a) and (CH2O)n (3) were preferentially screened (Table 1). After a meticulous investigation of the reaction parameters, the optimized conditions were identified as graphite plate (C+) as anode and platinum plate (Pt-) as cathode in a solvent mixture of MeCN and H2O at a 3:1 vol ratio at 60 ℃, wherein the target product BIIO (4aa) was obtained in 93% GC yield after 1.5 h (entry 1). As shown in entries 2 to 7, unsatisfying experimental results were obtained when using other electrode pairs in the electrochemical transformation. With pure MeCN as the reaction medium, only 42% GC yield of 4aa was observed (entry 8). No reaction occurred when water was used as the solvent, perhaps due to the insolubility of the reagents (entry 9). Varying the aqueous solutions did not provide an improved yield of 4aa (entries 10–12). A strong temperature effect was noticed. Performing the annulation at 25 ℃ only gave 22% GC yield of 4aa (entry 13). Increasing the temperature from 60 ℃ to 75 ℃ led to an inferior result (entry 14). Product 4aa was generated in 46% GC yield in the absence of (CH2O)n (entry 15), indicating that (CH2O)n played an important role in this reaction. No product was observed in the absence of electricity (entry 16). Performing the reaction under nitrogen atmosphere failed to give the target product (entry 17).

Table 1

Table 1. Optimization of reaction conditions.a

With the optimized reaction conditions in hand (Table 1, entry 1), the scope of the electrochemical [2 + 2 + 1] annulation was investigated. As shown in Scheme 2, the present electrochemical reaction was appropriate for a multitude of N-arylglycines. No matter whether the phenyl ring of N-phenylglycines was modified with either sterically hindered, electron-rich or electron-poor group, all of them gave the corresponding products (4aa-4an) in good to excellent yields. Many valuable functional-groups, such as alkyl (-Me, -iPr and -tBu), alkoxy (-OMe and -OCF3), methylthio (-SMe), trifluomethylthio (-SCF3) and halogen (F, Cl, Br and I) were introduced into the terminal products, proving the excellent functional group tolerance of this reaction. (3,4-Dimethylphenyl)glycine can also be used as the substrate, furnishing the annulation product 4ao in 84% yield. Importantly, N-functionalized glycine substrates with naphthalene (4ap) or heterocyclic ring (4aq and 4ar) were also compatible in the annulation system. No reaction occurred when pyridin-4-ylglycine or furan-3-ylglycine was used as the aminomethyl source. Electron-rich (4ba and 4ca) group-substituted as well as the electron-poor group-substituted benzo[d]isothiazole 1,1-dioxides (4da) delivered the annulation products in 82%−85% yields. Furthermore, when a regioisomeric mixture of 1e and 1e' was used, the corresponding products 4ea and 4ea' were formed as a mixture of regioisomeric with the same ratio.

Scheme 2

Scheme 2. Substrate scope. C plate (15 mm × 10 mm × 2 mm), Pt plate (15 mm × 10 mm × 0.1 mm), cathode, 1 (0.2 mmol), 2 (0.24 mmol), 3 (0.24 mmol), MeCN (2.25 mL), H2O (0.75 mL), I = 1 mA, r.t. 1.5 h, undivided cell. Isolated yields.

Next, the amplified reaction was carried out in order to further verify the practicality of electrolyte-free electrochemical annulation reaction (Scheme 3). Performing the reaction with 5 mmol 1a under the modified conditions gave the annulation product 4aa in 72% yield, demonstrating that the present reaction could be readily scalable.

Scheme 3

Scheme 3. Large-scale synthesis of 4aa.

Subsequently, a series of control experiments were carried out to gain insight into the reaction mechanism. Firstly, the radical-trapping experiment was conducted. The electro-oxidative annulation could be strongly suppressed by the radical scavenger butylated hydroxytoluene (BHT), and the BHT-CH2NHPh adduct 5aa was detected by mass spectroscopy (Scheme 4). This result revealed that the PhNHCH2 radical was the critical intermediate in the current reaction. Secondly, the intermittent electrolysis experiments were performed. This annulation proceeded or stop depending on electricity on/off, ruling out a radical chain mechanism (Fig. S2 in Supporting information). Finally, the cyclic voltammetry experiment was conducted to measure the redox potential of 1a and 2a. No oxidation peak of 1a was observed in the region of 0–1.75 V (vs. Ag/AgCl), suggesting the anodic oxidation of 1a was not easy to occur (Fig. S3 in Supporting information). With anhydrous MeCN as the solvent, 2a presented an oxidation peak at 1.35 V. The addition of water into MeCN solution led to an obviously reduced in the oxidation potential of 2a, and an oxidation potential of 2a was found at 0.93 V in MeCN/H2O (3:1). These results agreed with the yield of 4aa in MeCN aqueous solution and anhydrous MeCN (Table 1, entry 1 vs. 8). The reduction potential of 2a in anhydrous MeCN and MeCN/H2O (3:1) was recorded at −1.24 V and −0.82 V, respectively (Fig. S4 in Supporting information). And a similar decreased in reduction potential of 2a in the different volume of water of the reaction medium was also observed. The results suggested that the H-bond complex generated from 2a and water was more likely to be cathodically reduced [51].

Scheme 4

Scheme 4. Radical-capturing experiments.

Based on previous reports [7, 35, 51, 52] and the results of mechanism investigations, a plausible mechanism for the electrolyte-free electrochemical [2 + 2 + 1] annulation was proposed in Scheme 5 with taking 1a and 2a as an example. First, an H-bond association between 2a and water resulted in the generation of complex IM1, which was reduced into the carboxylate anion (IM2), water and hydrogen gas at the surface of platinum cathode. At the surface of graphite anode, the intermediate IM2 was oxidized into the oxygen-centred carboxyl radical IM3, which underwent decarboxylation to generate a carbon-centred aminomethyl radical IM4. Subsequently, the radical IM4 regio-selectively attacked benzo[d]isothiazole 1,1-dioxide 1a to produce a nitrogen-centred radical IM5, which abstracted a hydrogen atom from 2a to yield intermediate IM6 (detected by ESI-MS), followed by Mannich reaction with (CH2O)n to deliver a iminium ion intermediate IM7. Finally, this intermediate IM7 via the intramolecular cyclization and dehydrogenation sequences furnished the annulation product 4aa with the assistance of IM2.

Scheme 5

Scheme 5. Proposed reaction mechanism.

In summary, an H-bond promoted electrochemical [2 + 2 + 1] annulation of benzo[d]isothiazole 1,1-dioxides, N-arylglycines and (CH2O)n was successfully developed. This reaction allowed accessing various benzo[d]imidazo[1,5-b]isothiazole 5,5-dioxide derivatives in good to excellent yields. A paramount advantage of this method is that it does not require any catalyst, chemical oxidant, redox mediator and electrolyte. With (CH2O)n as the methylene source, this reaction offers a superior atom economy and practicability over the previous dual-component reactions. Mechanistic studies indicated that the hydrogen bond plays a vital role for generating the active PhNHCH2 radical at lower voltage. The present electrocatalytic reaction provides an economical and sustainable manner to make use of low-cost abundant paraformaldehyde, and would lead to tremendous applications in pharmaceutical chemistry and synthetic chemistry.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgment

We are grateful for financial support from Postgraduate Scientific Research Innovation Project of Hunan Province (No. CX20230949).

Supplementary materials

Supplementary material associated with this article can be found, in the online version, at doi:10.1016/j.cclet.2023.109246.

[1]

N. Devi, D. Singh, K.R. Rawal, J. Bariwal, V. Singh, Curr. Top. Med. Chem. 16 (2016) 2963–2994. doi: 10.2174/1568026616666160506145539

[2]A.K. Bagdi, A. Hajra, Org. Biomol. Chem. 18 (2020) 2611–2631. doi: 10.1039/D0OB00246A

[3]O.P.S. Patel, N.K. Nandwana, L.J. Legoabe, B.C. Das, A. Kumar, Adv. Synth. Catal. 362 (2020) 4226–4255. doi: 10.1002/adsc.202000633

[4]Y.H. Lu, C. Wu, J.C. Hou, et al., ACS Catal. 13 (2023) 13071–13076. doi: 10.1021/acscatal.3c02268

[5]J.F. Leal, B. Guerreiro, P.S.M. Amado, et al., Molecules 26 (2021) 1501. doi: 10.3390/molecules26061501

[6]E. Shang, Y. Wu, P. Liu, et al., Bioorg. Med. Chem. Lett. 24 (2014) 2764–2767. doi: 10.1016/j.bmcl.2014.04.006

[7]A. Shi, K. Sun, X. Chen, et al., Org. Lett. 24 (2022) 299–303. doi: 10.1021/acs.orglett.1c03960

[8]A. Shi, K. Sun, Y. Wu, et al., J. Catal. 415 (2022) 28–36. doi: 10.1016/j.jcat.2022.09.027

[9]X. Wang, A. Shi, X.Q. Huang, et al., Org. Biomol. Chem. 20 (2022) 3798–3802. doi: 10.1039/D2OB00460G

[10]N. Chen, H.C. Xu, Green Synth. Catal. 2 (2021) 165–178. doi: 10.1016/j.gresc.2021.03.002

[11]Y. Yuan, J. Yang, A. Lei, Chem. Soc. Rev. 50 (2021) 10058–10086. doi: 10.1039/D1CS00150G

[12]Z. Yang, Y. Yu, L. Lai, et al., Green Synth. Catal. 2 (2021) 19–26. doi: 10.1016/j.gresc.2021.01.009

[13]K. Sun, F. Xiao, B. Yu, W.M. He, Chin. J. Catal. 42 (2021) 1921–1943. doi: 10.1016/S1872-2067(21)63850-0

[14]D. Li, X. Wang, S. Li, et al., Chin. J. Org. Chem. 41 (2021) 4610–4622. doi: 10.6023/cjoc202107042

[15]Z.W. Hou, H.C. Xu, L. Wang, Curr. Opin. Electrochem. 34 (2022) 100988. doi: 10.1016/j.coelec.2022.100988

[16]S. Mu, H. Li, Z. Wu, et al., Chin. J. Org. Chem. 42 (2022) 4292–4299. doi: 10.6023/cjoc202211002

[17]S. Cheng, C. Ou, H. Lin, et al., Chin. J. Org. Chem. 41 (2021) 4718–4724. doi: 10.6023/cjoc202110019

[18]J.Y. Chen, C.T. Zhong, Q.W. Gui, et al., Chin. Chem. Lett. 32 (2021) 475–479. doi: 10.1016/j.cclet.2020.09.034

[19]W. Li, Y. Tang, W. Ouyang, et al., Chin. J. Org. Chem. 41 (2021) 4766–4772. doi: 10.6023/cjoc202109044

[20]Y. Han, X. Cui, Chin. J. Org. Chem. 41 (2021) 2929–2931. doi: 10.6023/cjoc202100056

[21]Y. Wu, J.Y. Chen, H.R. Liao, et al., Green Synth. Catal. 2 (2021) 233–236. doi: 10.1016/j.gresc.2021.03.006

[22]H.F. Liu, M.X. He, H.T. Tang, Org. Chem. Front. 9 (2022) 5955–5961. doi: 10.1039/D2QO01281B

[23]L. Ding, K. Niu, Y. Liu, Q. Wang, Chin. Chem. Lett. 33 (2022) 4057–4060. doi: 10.1016/j.cclet.2021.12.053

[24]X. Wang, S. Wu, Y. Zhong, et al., Chin. Chem. Lett. 34 (2023) 107537. doi: 10.1016/j.cclet.2022.05.051

[25]Y.H. Lu, S.Y. Mu, H.X. Li, et al., Green Chem. 25 (2023) 5539–5542. doi: 10.1039/D2GC04906F

[26]Q. Wang, X.J. Meng, H.T. Tang, et al., Green Chem. 25 (2023) 2572–2576. doi: 10.1039/D2GC04544C

[27]J. Jiang, K.L. Wang, X. Li, et al., Chin. Chem. Lett. 34 (2023) 108699. doi: 10.1016/j.cclet.2023.108699

[28]H.T. Tang, J.S. Jia, Y.M. Pan, Org. Biomol. Chem. 18 (2020) 5315–5333. doi: 10.1039/D0OB01008A

[29]F. Lian, K. Xu, C. Zeng, Chem. Rec. 21 (2021) 2290–2305. doi: 10.1002/tcr.202100036

[30]Z.L. Wu, J.Y. Chen, X.Z. Tian, et al., Chin. Chem. Lett. 33 (2022) 1501–1504. doi: 10.1016/j.cclet.2021.08.071

[31]T. Feng, S. Wang, Y. Liu, S. Liu, Y. Qiu, Angew. Chem. Int. Ed. 61 (2022) e202115178. doi: 10.1002/anie.202115178

[32]Z. Tan, F. Xiang, K. Xu, C. Zeng, Org. Lett. 24 (2022) 5345–5350. doi: 10.1021/acs.orglett.2c01983

[33]Y.H. Lu, Z.T. Zhang, H.Y. Wu, et al., Chin. Chem. Lett. 34 (2023) 108036. doi: 10.1016/j.cclet.2022.108036

[34]T. Feng, Z. Zhu, D. Zhang, et al., Green Chem. 25 (2023) 2681–2689. doi: 10.1039/D3GC00344B

[35]J.F. Cui, W.Q. Zhong, J.M. Huang, J. Org. Chem. 88 (2023) 1147–1154. doi: 10.1021/acs.joc.2c02654

[36]R. Francke, R.D. Little, Chem. Soc. Rev. 43 (2014) 2492–2521. doi: 10.1039/c3cs60464k

[37]H. Long, C. Huang, Y.T. Zheng, et al., Nat. Commun. 12 (2021) 6629. doi: 10.1038/s41467-021-26960-y

[38]L. Han, M. Huang, Y. Li, et al., Org. Chem. Front. 8 (2021) 3110–3117. doi: 10.1039/D1QO00038A

[39]F. Lu, K. Zhang, Y. Yao, et al., Green Chem. 23 (2021) 763–766. doi: 10.1039/D0GC03590D

[40]J. Jiang, Z. Wang, W.M. He, Chin. Chem. Lett. 32 (2021) 1591–1592. doi: 10.1016/j.cclet.2021.02.067

[41]Y. Zhang, H. Gao, J. Guo, H. Zhang, X. Yao, Chem. Commun. 57 (2021) 13166–13169. doi: 10.1039/D1CC05208J

[42]Y. Yuan, L.S. Li, L. Zhang, et al., Chem. Commun. 57 (2021) 2768–2771. doi: 10.1039/D1CC00486G

[43]P. Ghosh, A. Hajra, Adv. Synth. Catal. 364 (2022) 4157–4165. doi: 10.1002/adsc.202200932

[44]W.B. He, S.J. Zhao, J.Y. Chen, et al., Chin. Chem. Lett. 34 (2023) 107640. doi: 10.1016/j.cclet.2022.06.063

[45]C. Liu, W. Huang, J. Zhang, et al., Green Chem. 23 (2021) 1447–1465. doi: 10.1039/D0GC04124F

[46]X. Cheng, H. Wang, F. Xiao, G.J. Deng, Green Chem. 18 (2016) 5773–5776. doi: 10.1039/C6GC02319C

[47]T. Wan, S. Du, C. Pi, et al., ChemCatChem 11 (2019) 3791–3796. doi: 10.1002/cctc.201801512

[48]H. Wang, Y. Huang, Q. Jiang, X. Dai, F. Shi, Chem. Commun. 55 (2019) 3915–3918. doi: 10.1039/C8CC10309G

[49]F. Xiao, Y. Hu, H. Huang, F. Xu, G.J. Deng, Org. Biomol. Chem. 18 (2020) 3527–3535. doi: 10.1039/D0OB00362J

[50]Y.H. Lu, S.Y. Mu, J. Jiang, et al., ChemSusChem 16 (2023) e202300523. doi: 10.1002/cssc.202300523

[51]F. Zhao, N. Meng, T. Sun, et al., Org. Chem. Front. 8 (2021) 6508–6514. doi: 10.1039/D1QO01351C

[52]S. Li, X. Li, T. Wang, et al., Adv. Synth. Catal. 364 (2022) 2346–2351. doi: 10.1002/adsc.202200339

网址:Supporting https://klqsh.com/news/view/151522

相关内容

Oscars 2025: Complete winners listOscars 2025: The complete list of winners

2025 Oscar Winners: The Complete List of 97th Academy Awards

2025 Academy Awards: The Full List of Winners

Environmental health

Find an Infusion Center

Shinedown: Dance, Kid, Dance Tour

Oscar Nominations 2025: The Full List of Nominees

About

FYU 是 For Your Understanding 的缩写,意思是“为了你的理解”